Community

A group of cooperating humans acting as purposeful systemunder a value capturing business model (e.g. like in Open Source communities).

Industrial Revolution

“The Industrial Revolution was a period from 1750 to 1850 where changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times. It began in the United Kingdom, then subsequently spread throughout Western Europe, North America, Japan, and eventually the rest of the world.

The Industrial Revolution marks a major turning point in history; almost every aspect of daily life was influenced in some way. Most notably, average income and population began to exhibit unprecedented sustained growth. In the two centuries following 1800, the world’s average per capita income increased over tenfold, while the world’s population increased over sixfold.”

[Wikipedia contributors. “Industrial Revolution.” Wikipedia, the Free Encyclopedia. Wikimedia Foundation, Inc., August 24, 2012. ]

Internet of Things (IoT)

“The future Internet of Things links uniquely identifiable things to their virtual representations in the Internet containing or linking to additional information on their identity, status, location or any other business, social or privately relevant information at a financial or non-financial pay-off that exceeds the efforts of information provisioning and offers information access to non-predefined participants. The provided accurate and appropriate information may be accessed in the right quantity and condition, at the right time and place at the right price. The Internet of Things is not synonymous with ubiquitous/pervasive computing, the Internet Protocol (IP), communication technology, embedded devices, its applications, the Internet of People or the Intranet/Extranet of Things, yet it relies on all of these approaches.” [Uckelmann et al. 2011] (page 8)

“The future Internet of Things links uniquely identifiable things to their virtual representations in the Internet containing or linking to additional information on their identity, status, location or any other business, social or privately relevant information at a financial or non-financial pay-off that exceeds the efforts of information provisioning and offers information access to non-predefined participants. The provided accurate and appropriate information may be accessed in the right quantity and condition, at the right time and place at the right price. The Internet of Things is not synonymous with ubiquitous/pervasive computing, the Internet Protocol (IP), communication technology, embedded devices, its applications, the Internet of People or the Intranet/Extranet of Things, yet it relies on all of these approaches.” [Uckelmann et al. 2011] (page 8)

Internet of Services

The Internet of Services extends today’s internet with a software service layer to enable business services between organizations, companies, and individuals.

The Internet of Services extends today’s internet with a software service layer to enable business services between organizations, companies, and individuals.

Muda

see Toyota Production System

Purposeful Systems

Definition in accordance with Ackoff’s approach [Ackoff 1972]: “Systems or their parts are purposeful if, by their choices, they can produce (a) the same outcome in different ways in the same environment and (b) different outcomes in the same and different environments.”

Definition in accordance with Ackoff’s approach [Ackoff 1972]: “Systems or their parts are purposeful if, by their choices, they can produce (a) the same outcome in different ways in the same environment and (b) different outcomes in the same and different environments.”

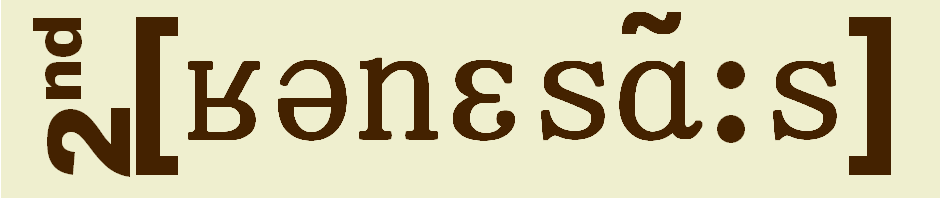

Renaissance (First)

The Renaissance or “rebirth” is the progressive, intellectual, and cultural epoch between the 14th-17th century starting in North Italy and spreading out to countries in central Europe.

The Renaissance or “rebirth” is the progressive, intellectual, and cultural epoch between the 14th-17th century starting in North Italy and spreading out to countries in central Europe.

An extensive bibliography is available in [Toman 2011, pp. 451-458] and an interesting sociological technology study confirming our findings can be found in [Weyer 2008, pp. 123–139.]

Visual Artists of the Renaissance

Famous visual artists of the renaissance include Antonello da Messina (1430-1479), Gentile Bellini (1429-1507), Antonio del Pollaiuolo (1432-1498), Sandro Botticelli (1445-1510), Leonardo da Vinci (1452-1519), Donatelle (1386-1466), Giotto di Bondone (1266-1337)

Writers of the Renaissance

Famous writers of the renaissance include Giovanni Pico della Mirandola (1463-1494 ), Dante Alighieri (1265-1321), Francesco Petrarca (1304-1374), Giovanni Boccaccio (1313-1375)

Printing

Woodcut and other forms of printing had existed for a long time. Movable type was Gutenberg’s key innovation. The effect was staggering.

Woodcut and other forms of printing had existed for a long time. Movable type was Gutenberg’s key innovation. The effect was staggering.

Toyota Production System

“The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS organizes manufacturing and logistics for the automobile manufacturer, including interaction with suppliers and customers. The system is a major precursor of the more generic “lean manufacturing.” Taiichi Ohno, Shigeo Shingo and Eiji Toyoda developed the system between 1948 and 1975.[1]

“The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS organizes manufacturing and logistics for the automobile manufacturer, including interaction with suppliers and customers. The system is a major precursor of the more generic “lean manufacturing.” Taiichi Ohno, Shigeo Shingo and Eiji Toyoda developed the system between 1948 and 1975.[1]

Originally called “just-in-time production,” it builds on the approach created by the founder of Toyota, Sakichi Toyoda, his son Kiichiro Toyoda, and the engineer Taiichi Ohno. The principles underlying the TPS are embodied in The Toyota Way.” [Wikipedia]

Muda

Muda (無駄?) is a Japanese word meaning “futility; uselessness; idleness; superfluity; waste; wastage; wastefulness”,[1] and is a key concept in the Toyota Production System (TPS) as one of the three types of waste (muda, mura, muri).[2] Waste reduction is an effective way to increase profitability. Toyota merely picked up these three words beginning with the prefix mu-,[3] which in Japan are widely recognized as a reference to a product improvement program or campaign. A process adds value by producing goods or providing a service that a customer will pay for. A process consumes resources and waste occurs when more resources are consumed than are necessary to produce the goods or provide the service that the customer actually wants. The attitudes and tools of the TPS heighten awareness and give whole new perspectives on identifying waste and therefore the unexploited opportunities associated with reducing waste.

Muda (無駄?) is a Japanese word meaning “futility; uselessness; idleness; superfluity; waste; wastage; wastefulness”,[1] and is a key concept in the Toyota Production System (TPS) as one of the three types of waste (muda, mura, muri).[2] Waste reduction is an effective way to increase profitability. Toyota merely picked up these three words beginning with the prefix mu-,[3] which in Japan are widely recognized as a reference to a product improvement program or campaign. A process adds value by producing goods or providing a service that a customer will pay for. A process consumes resources and waste occurs when more resources are consumed than are necessary to produce the goods or provide the service that the customer actually wants. The attitudes and tools of the TPS heighten awareness and give whole new perspectives on identifying waste and therefore the unexploited opportunities associated with reducing waste.

Muda has been given much greater attention as waste than the other two which means that whilst many Lean practitioners have learned to see muda they fail to see in the same prominence the wastes of mura (unevenness) and muri (overburden). Thus whilst they are focused on getting their process under control they do not give enough time to process improvement by redesign.” [Wikipedia]

What’s up to every body, it’s my first go to see of this blog;

this website carries amazing and in fact fine material designed for visitors.